The moment I shook the previous owner’s hand, and drove away my new second vehicle, an AMC Eagle, it stalled leaving the parking lot and I barely hobbled home with it. I knew I had my work cut out for me. First thing it needed was to eliminate the ancient and malfunctioning computer controlled carburetor.

Here is a Motorcraft 2150 mechanical carburetor which is the aftermarket carb of choice for Eagles, this carb is a simple unit and nothing special, but it works at nearly any angle, so the symptom of stalling around corners is a thing of the past. I have it connected to a manual choke, like a small aircraft.

The next thing to be taken care of was the sagging rear, I ordered some new leaf springs and shackles, this gave an inch in addition to the original factory ride-height.

With the main problems cleared away, I could turn to more cosmetic work, using a spray can and some enamel model paint, I refurbished the front grille.

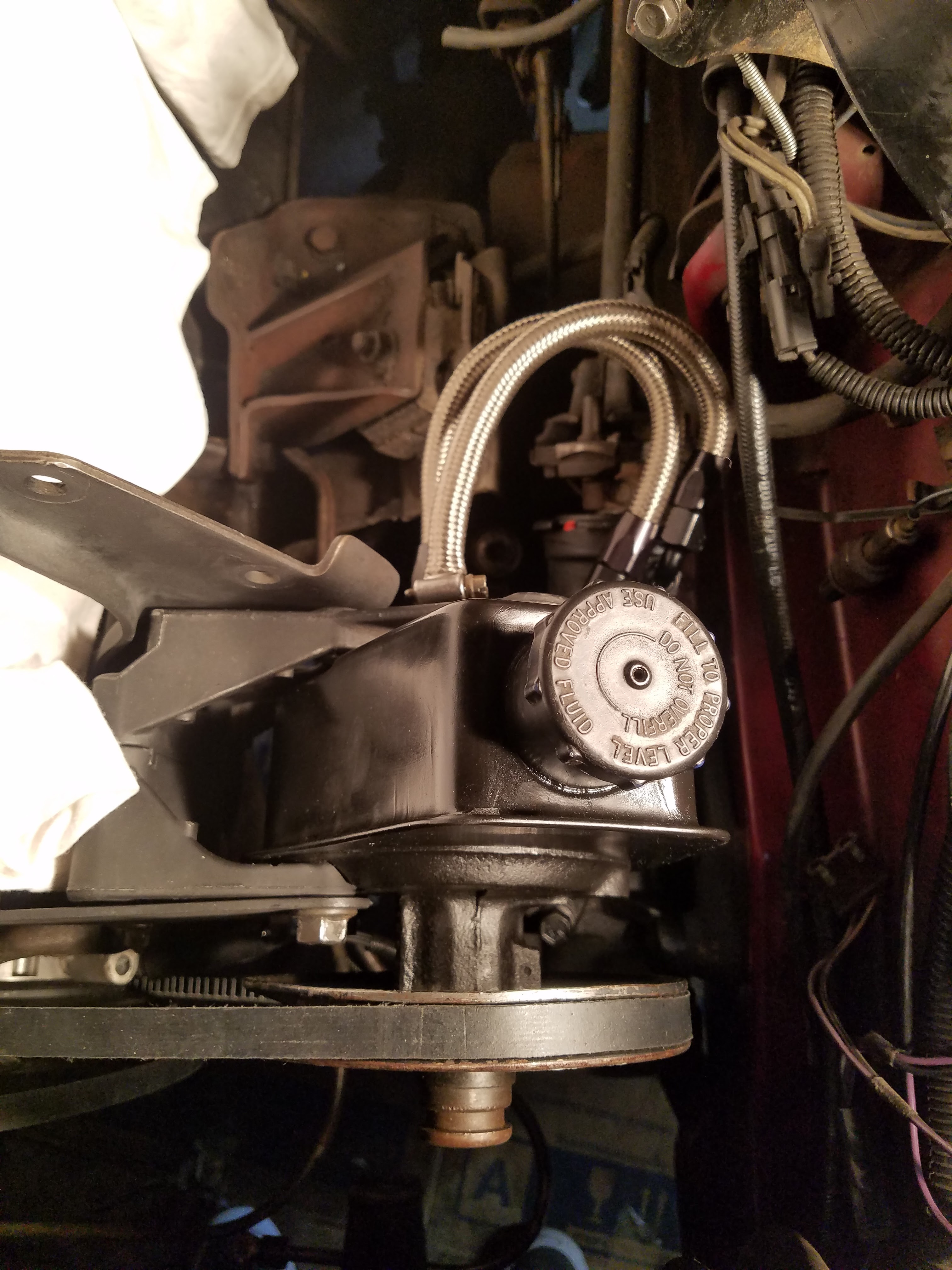

I did some inspection and what looked like a minor leak from the orientation in which it was installed, the leak previously hidden was now very apparent. This was the source of my brake pedal sag problems.

The new boster unit installed. The brakes now dont sag, and in fact they are now the most responsive brakes on any vehicle I have owned or driven.

Doing some research, I found many older Jeep Cherokee 5 lug wheels are an exact match. I picked up a set of 4 from the slavage yard and mounted them to some Goodyear Wrangler tires. Unfortunately one of the previous owners had cut the outside fender for clearance for the set of tires they had on. This modification should have been done to the inside fender so it is not visible, but what was done is done. The larger softer tires give the suspension and frame of this car a reprieve and the aluminum wheels reduce unsprung mass. This in addition to some new ball joints greatly improved ride quality.

It was at this point I thought I was free from major maintenance issues. That was until I saw a tiny brown flake hanging from inside the wheel well…

I discovered the driver’s side floor panel was completely rusted through. I determined it was salvageable so I bought an angle grinder and learned how to weld, first SMAW, then GMAW. I decided to use GMAW for the weld because it worked best to connect the thinner the sheet metal to the thicker unibody frame.

I discovered the driver’s side floor panel was completely rusted through. I determined it was salvageable so I bought an angle grinder and learned how to weld, first SMAW, then GMAW. I decided to use GMAW for the weld because it worked best to connect the thinner the sheet metal to the thicker unibody frame.

First tacks after grinding the old panel away to bare unrusted metal.

Many times this type of rust is caused by water hanging out in the carpets from wet boots and shoes.

After a successful weld job, I weatherproofed the undercarriage with some heavy duty spray-tar coating.

The bare floor is visible in this picture, it is very solid and turned out much better than I was dreading when I first noticed the massive rust hole.

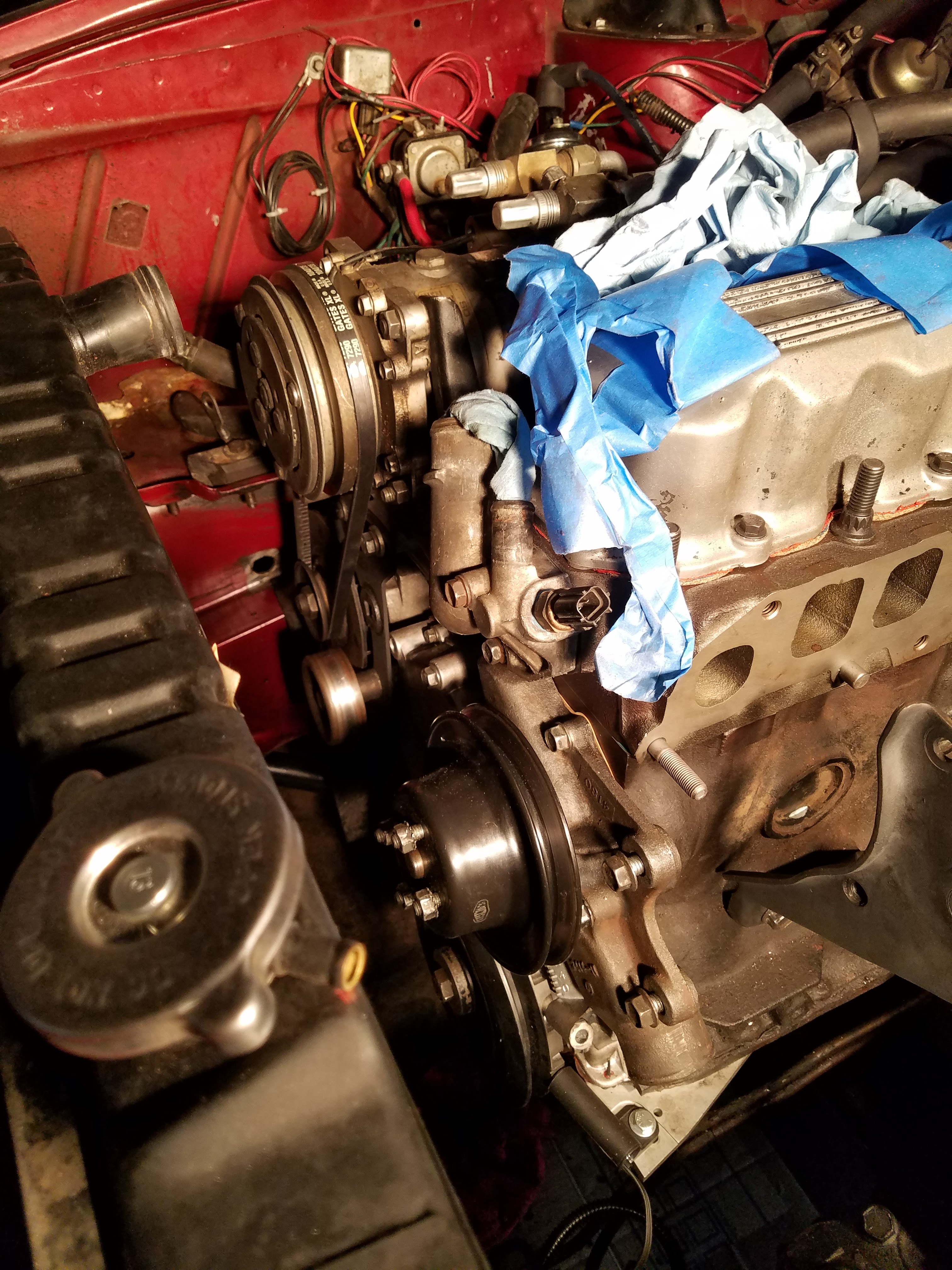

The next step was to swap the cylinder head with a donor from a Jeep Cheorkee and change from carbureted to electronic fuel injection, I needed to do lots of research, design and trips to the scrapyard before getting it back on the road

New cylinder head in place

New power steering pump and lines in place

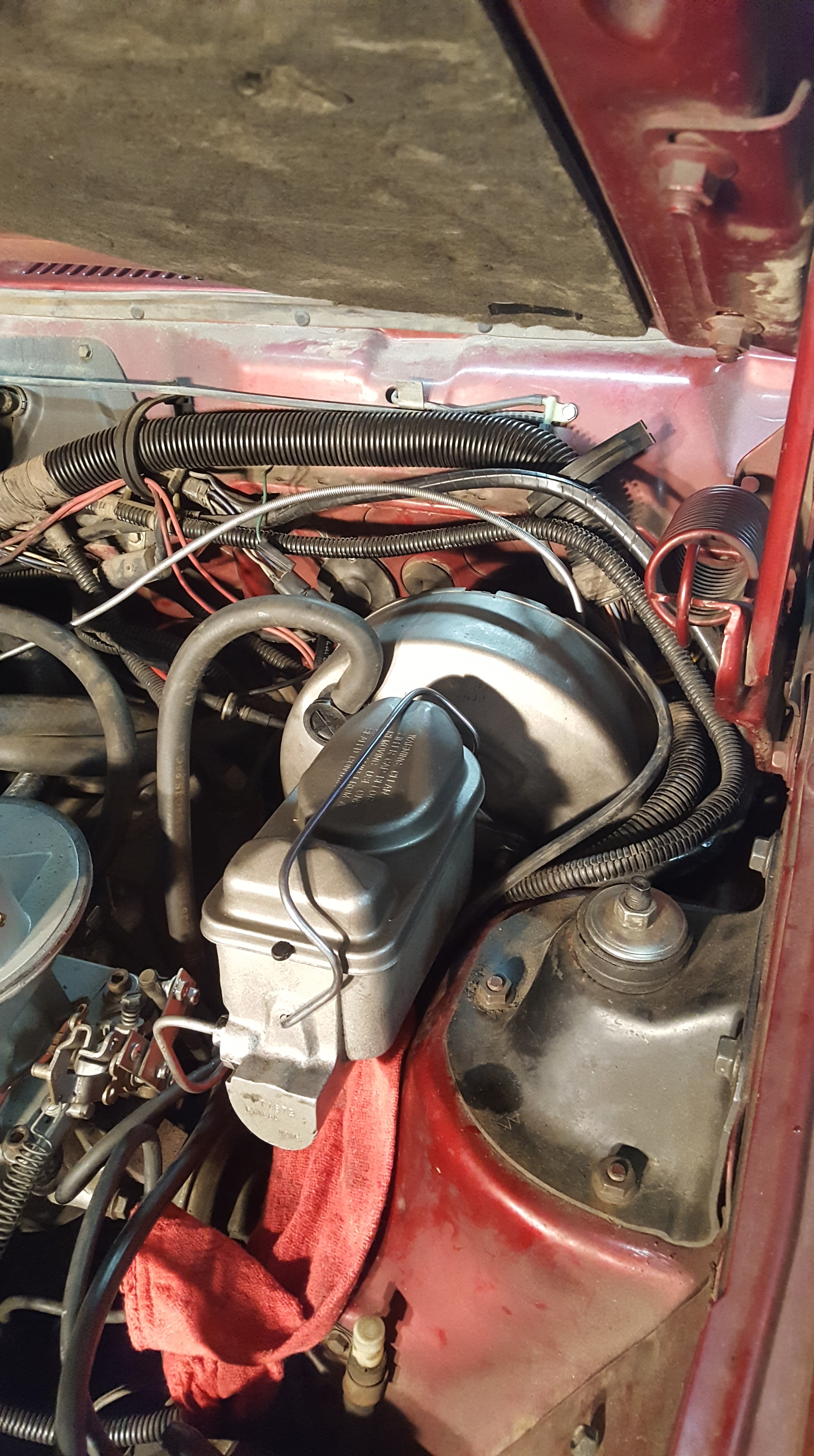

sorting out the new ignition system wiring from the old

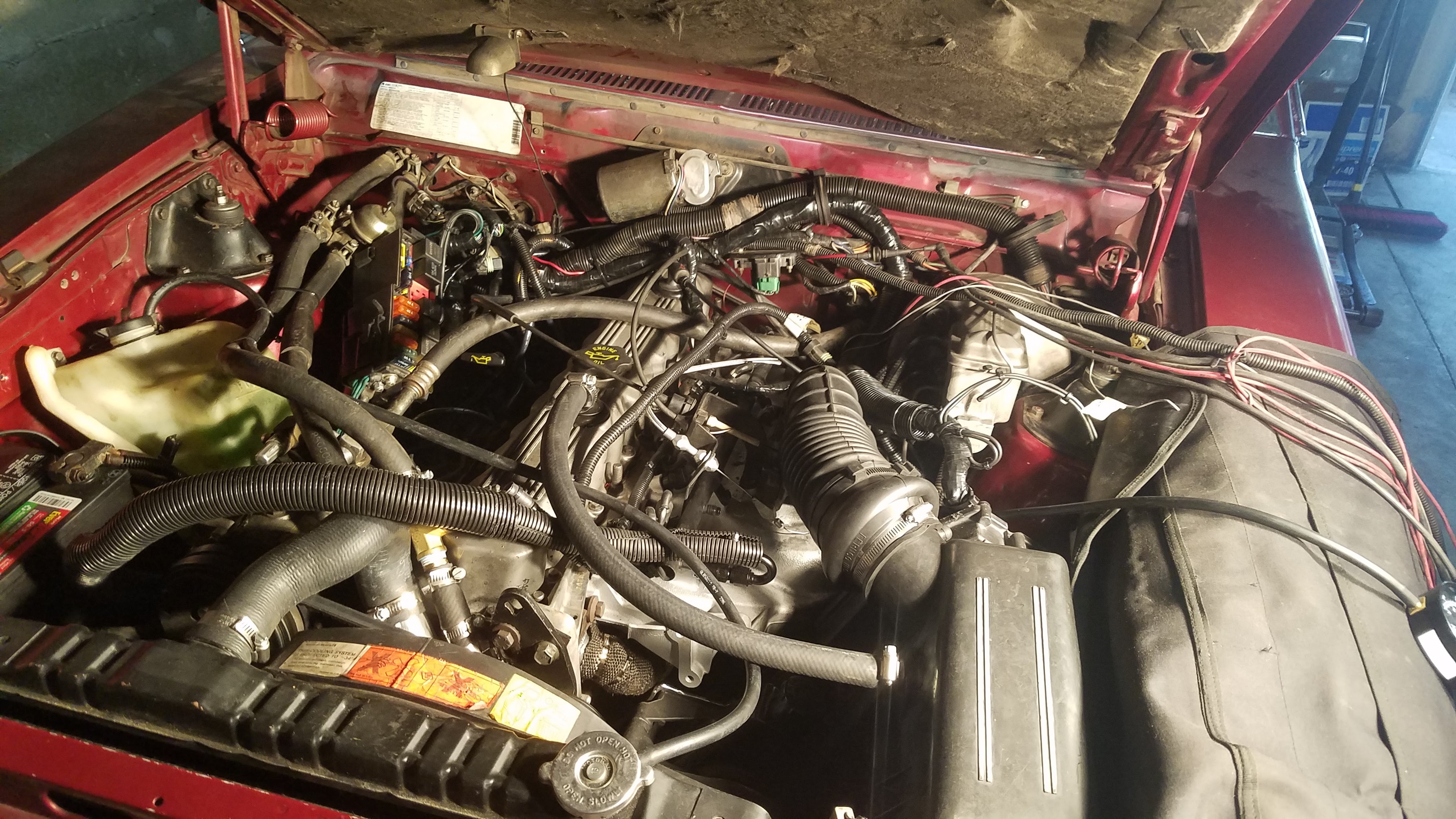

Intake manifold, air intake and coolant resorvoir from donor vehicle relocated and installed

Sorting the donor wiring harness integration into the exisintg one

Testing the selec-trac 4wd system with the wheels off

Still needs to be tuned to pass emissions, failed the last few tests. This model year is 1 year after the “classic car” no emissions cutoff status so they have to put it onto a 4 wheel dyno and take it up to 80mph, 5 mph past the speedometer limit of 75, unreal.